This case study examines the lubrication process for bearings in an infrared machine within the extrusion sector of a prominent plastics manufacturing facility. These bearings operate continuously at temperatures of 200°C, necessitating effective lubrication to ensure performance and longevity. The project was implemented for a well-known company in the industry, emphasizing the importance of maintaining their high operational standards.

MEMOLUB® HPS

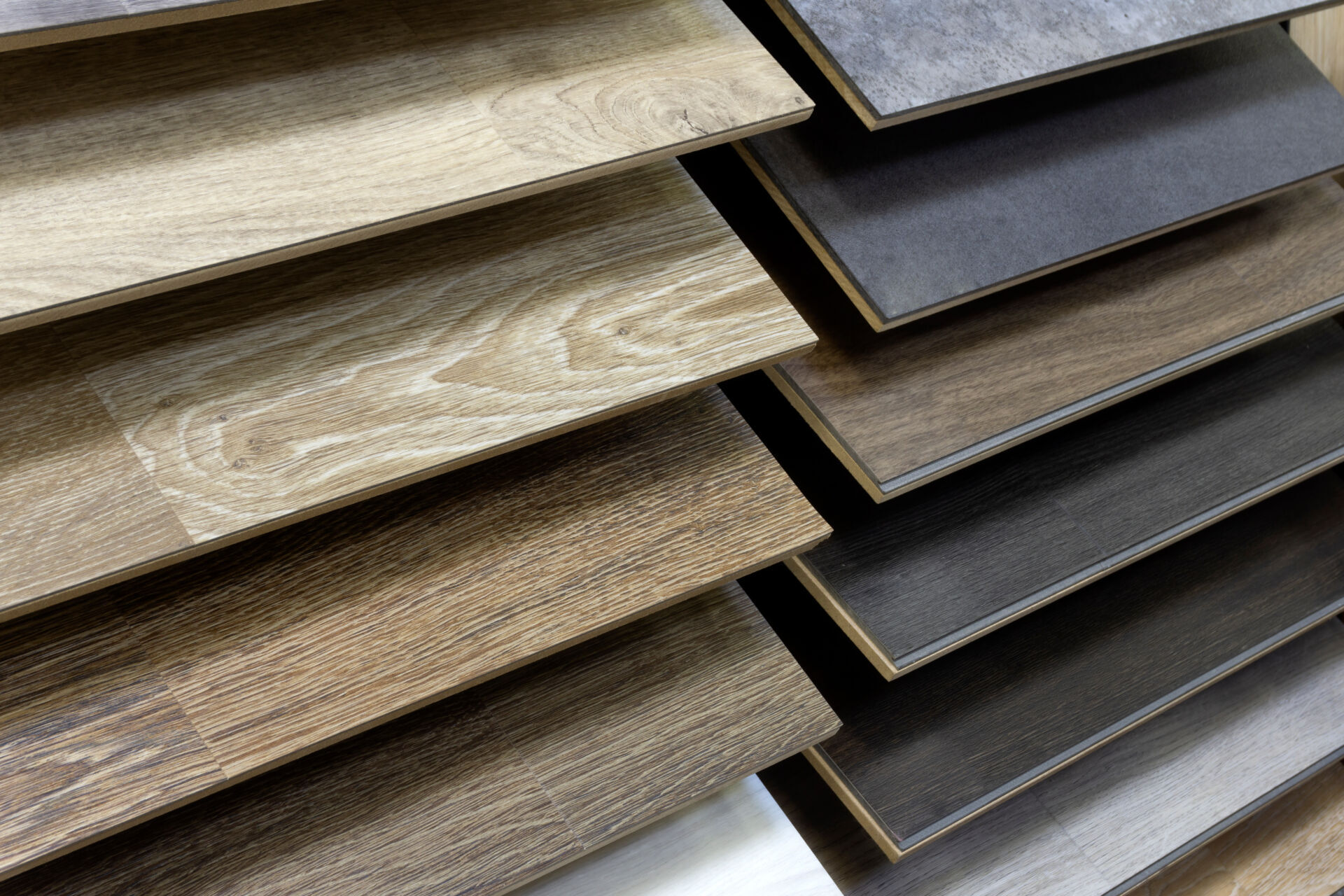

Automating lubrication for infrared machine bearings at a vinyl floor factory.

CONTEXT

PROBLEM

The bearings, subjected to extreme temperatures, are difficult to access, making manual lubrication with the recommended grease both hazardous and time-consuming for operators. Ensuring regular maintenance under these challenging conditions was problematic, leading to potential safety risks and inefficiencies.

SOLUTION

A Memolub HPS automatic lubricator was installed in a single-point configuration, utilising Castrol's BRAYCOTE 2115 2 grease. This setup provided consistent lubrication, eliminating the need for manual intervention and ensuring the safety of the operators.

Results

Since the implementation of the Memolub HPS system, there have been no bearing failures. The automated lubrication process ensured that the bearings remained well-lubricated, enhancing both the reliability and safety of the operation. This solution has significantly improved the efficiency and maintenance processes within the high-temperature conditions of the extrusion sector in the plastics industry. The maintenance staff experienced a reduction in manual labor, and the overall operational efficiency of the facility was enhanced.

Memolub® HPS

- Reusable autonomous single & multi-point lubrication system.

- Battery powered.

- 25 bar ejection pressure.

- Up to 8 outlets.

- Remote installation up to 8 m.

- 52 Settings.