Operating on a 24/7 schedule with 3x8-hour shifts, a multinational cable production company in Italy faced challenges in maintenance and lubrication. Despite attempts with gas lubricators, system failures led to costly production downtime, amounting to approximately €100,000 per day.In response, they reverted to manual lubrication, prioritising reliability over automated efficiency.

MEMOLUB® HPS / EPS

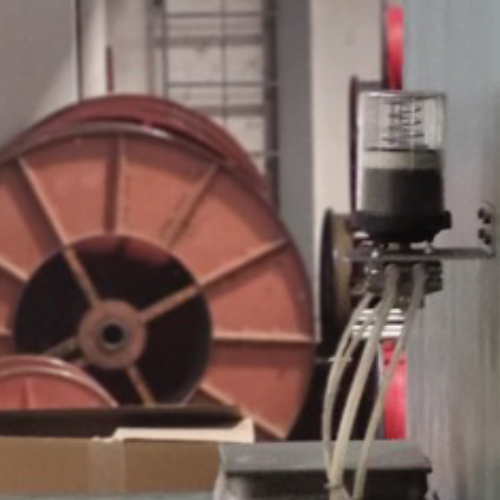

Lubrication of the bearings of a single and double cable drum twister.

BACKGROUND

THE PROBLEM

Manual lubrication, scheduled biweekly, necessitates production and machinery shutdowns. Workforce reluctance adds a layer of complexity. In critical applications with high-speed and heavy loads, meticulous lubrication is essential, but difficult access poses challenges. The high cost of spare parts and the risk of wire contamination from excess lubricant amplify concerns.

THE SOLUTION

Over a 12-month trial with a maintenance partner, 44 Memolub EPS and HPS units were installed, complemented by Castrol's high-performance-grease Optitemp LG2. 24V driven Memolub lubricators were strategically introduced to optimize lubrication with production. Where necessary, the customer installed its Memolub solutions outside the machines.

Results

- Maintenance Time saved per year : 248,4 hours

- 44 units were installed to lubricant 138 points

- 3 minutes average per point

- 26 manual lubrication sessions, 1 every 2 weeks.

- 138 points x 3 min x 26 sessions = 14904 min/year

- Lubricant consumption has been reduced, including 7 units being recalibrated from a 6 months to 12 months cartridge refill pace.

- The customer is 100% sure that the lubrication is done.

- Cleaner lubrication, decreased risk of production contamination

before