- Do not open the housing: loaded spring

- Hold MEMOLUB® down during manual checks

- Leq <70 dB

- Use MEMOLUB® only for greasing machinery

- Use only lubricant cartridges and batteries recommended by the manufacturer

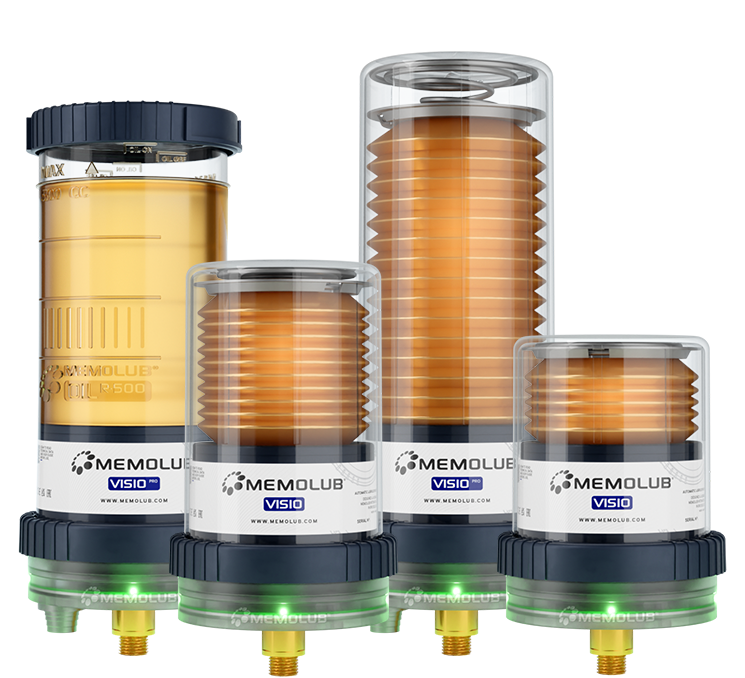

MEMOLUB VISIO SERIES KNOWLEDGE BASE

Ref. IDs: 6300, 6311, 6312, 6313, 6321, 6322, 6323, 1620, 6317, 6327

Dimensions

120CC

Grease & Oil

120cc I 4oz

240CC

Grease & Oil

240cc I 8.1oz

480CC

Grease & Oil

480cc I 16.2oz

OIL R-500

Refillable Oil Reservoir

500cc I 16.9oz

Precautions

Settings & Feedback

FREQUENCY SETTINGS

2ND GENERATION (SERIAL NUMBERS VIS-XX-XXXX & VPR-XX-XXXX)

| WHEEL POSITION | DOSING PERIODICITY | MAX. DAILY OUTPUT* | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (120CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (240CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (480CC) |

|---|---|---|---|---|---|

| 0** | External (PLC) | ||||

| 1 | 48 hours | 0.3 cc/day | 12 months | 24 months*** | 48 months*** |

| 2 | 24 hours | 0.6 cc/day | 6 months | 12 months | 24 months*** |

| 3 | 16 hours | 0.9 cc/day | 4 months | 8 months | 16 months*** |

| 4 | 12 hours | 1.2 cc/day | 3 months | 6 months | 12 months |

| 5 | 8 hours | 1.8 cc/day | 2 months | 4 months | 8 months |

| 6 | 6 hours | 2.4 cc/day | 1.5 month | 3 months | 6 months |

| 7 | 4 hour | 3.6 cc/day | 1 month | 2 months | 4 months |

| 8 | 2 hour | 7.2 cc/day | 0.5 month | 1 month | 2 months |

| 9 | 1 hour | 14.4 cc/day | 0.25 month | 0.5 month | 1 month |

*Maximum daily output without stroke washers.

** Only available on Memolub Visio Pro models.

*** Please consider lubricant expiry date for long cartridge lifetimes.

1ST GENERATION (All other serial numbers)

| WHEEL POSITION | DOSING PERIODICITY | MAX. DAILY OUTPUT* | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (120CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (240CC) | REFILLING FREQUENCY VS. CARTRIDGE CONTENT (480CC) |

|---|---|---|---|---|---|

| 0** | External (PLC) | ||||

| 1 | 24 hours | 0.6 cc/day | 6 months | 12 months | 24 months*** |

| 2 | 16 hours | 0.9 cc/day | 4 months | 8 months | 16 months*** |

| 3 | 12 hours | 1.2 cc/day | 3 months | 6 months | 12 months |

| 4 | 8 hours | 1.8 cc/day | 2 months | 4 months | 8 months |

| 5 | 4 hours | 3.6 cc/day | 1 month | 2 months | 4 months |

| 6 | 2 hours | 7.2 cc/day | 0,5 month | 1 month | 2 months |

| 7 | 1 hour | 14.4 cc/day | 0,25 month | 0,5 month | 1 month |

| 8 | 1/2 hour | 28.8 cc/day | 4 days | 0,25 month | 0,5 month |

| 9 | 1/4 hour | 57.6 cc/day | 2 days | 4 days | 0,25 month |

* Maximum daily output without stroke washers.

** Only available on Memolub Visio EP models

*** Please consider lubricant expiry date for long cartridge lifetimes.

VOLUME SETTINGS [cm³/day]

2ND GENERATION (SERIAL NUMBERS VIS-XX-XXXX & VPR-XX-XXXX)

By using stroke washers you can adjust the amount of lubricant discharged per pumping cycle.

| NUMBER OF STROKE WASHERS | WHEEL POSITION | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| - | External (PLC) | 0.3 | 0.6 | 0.9 | 1.2 | 1.8 | 2.4 | 3.6 | 7.2 | 14.4 |

|

0.28 | 0.56 | 0.84 | 1.12 | 1.7 | 2.2 | 3.4 | 6.7 | 13.5 | |

+ +

|

0.26 | 0.52 | 0.79 | 1.04 | 1.62 | 2.1 | 3.15 | 6.3 | 12.6 | |

2  + +

|

0.24 | 0.49 | 0.73 | 0.98 | 1.46 | 1.95 | 2.92 | 5.85 | 11.7 | |

3  + +

|

0.22 | 0.45 | 0.67 | 0.9 | 1.35 | 1.8 | 2.7 | 5.4 | 10.8 | |

4  + +

|

0.2 | 0.41 | 0.62 | 0.82 | 1.23 | 1.65 | 2.47 | 4.95 | 9.9 | |

5  + +

|

0.18 | 0.37 | 0.55 | 0.74 | 1.1 | 1.5 | 2.2 | 4.5 | 9 | |

6  + +

|

0.17 | 0.34 | 0.5 | 0.68 | 1 | 1.35 | 2.02 | 4.05 | 8.1 | |

*The circlip must always be added on top of the washers.

The circlip must always be added on top of the washers.

1ST GENERATION (All other serial numbers)

By using stroke washers you can adjust the amount of lubricant discharged per pumping cycle.

| NUMBER OF STROKE WASHERS | WHEEL POSITION | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| - | N/A | 0.6 | 0.9 | 1.2 | 1.8 | 3.6 | 7.2 | 14.4 | 28.8 | 57.6 |

|

0.56 | 0.84 | 1.12 | 1.69 | 3.4 | 6.7 | 13.5 | 27 | 54 | |

+ +

|

0.52 | 0.79 | 1.04 | 1.58 | 3.15 | 6.3 | 12.6 | 25.2 | 50.4 | |

2  + +

|

0.49 | 0.73 | 0.98 | 1.46 | 2.92 | 5.85 | 11.7 | 23.4 | 46.8 | |

3  + +

|

0.45 | 0.67 | 0.9 | 1.35 | 2.7 | 5.4 | 10.8 | 21.6 | 43.2 | |

4  + +

|

0.41 | 0.62 | 0.82 | 1.24 | 2.47 | 4.95 | 9.9 | 19.8 | 39.6 | |

5  + +

|

0.37 | 0.56 | 0.74 | 1.1 | 2.2 | 4.5 | 9 | 18 | 36 | |

6  + +

|

0.34 | 0.51 | 0.68 | 1 | 2.02 | 4.05 | 8.1 | 16.2 | 32.4 | |

VISUAL FEEDBACK

2ND GENERATION (SERIAL NUMBERS VIS-XX-XXXX & VPR-XX-XXXX)

| COLOR | STATUS |

|---|---|

|

|

The testrun has been activated through pushbutton . / The pumping cycle ran successfully. |

|

|

Battery low / Lubricant cartridge empty. |

|

|

The gearbox/motor is damaged or broken. / The pipe may be clogged. |

1ST GENERATION (All other serial numbers)

| COLOR | STATUS |

|---|---|

|

|

The gearbox motor is damaged or broken. The tube might be clogged. |

|

|

The battery is low. |

|

|

Abnormal temperature is detected or there is an issue with the pump. |

|

|

The testrun activation via the touchpad was successful. |

REMOTE INSTALLATION DISTANCES

| TYPE OF INSTALLATION | MAXIMUM DISTANCE* |

|---|---|

| Single point | 8m |

| Multipoint with 2 outlets | 6m |

| Multipoint with 4 outlets | |

| Multipoint with 6 outlets | |

| Multipoint with 8 outlets | |

| Multipoint with 10 outlets | Contact your distributor. |

| Multipoint with 12 outlets |

*The maximum distances are valid for a variety of lubricants, both oils and greases with a viscosity level up to NGLI2.

REMOTE CONTROL

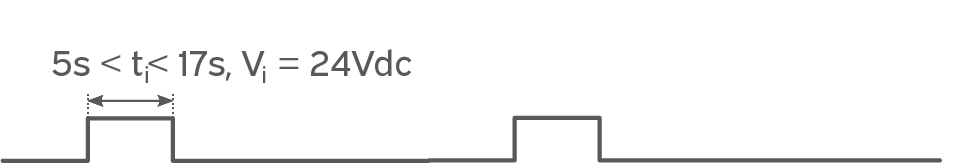

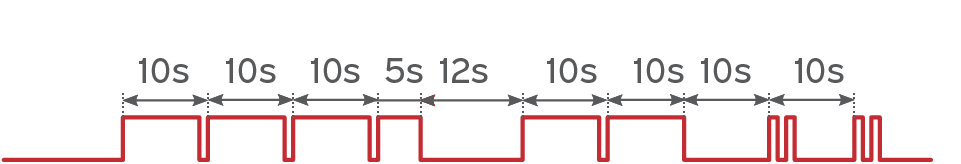

INTERMITTENT MODE

MEMOLUB VISIO PRO

| DESCRIPTION | SIGNAL |

|---|---|

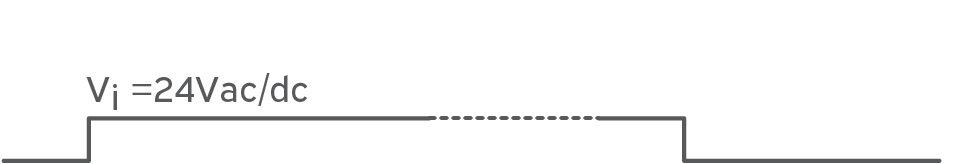

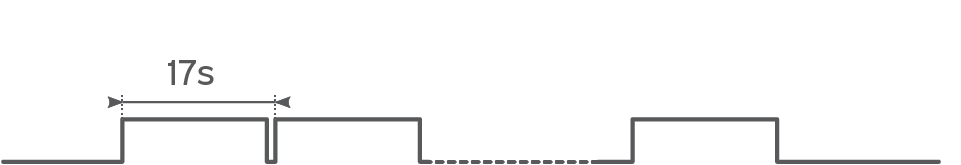

| INPUT SIGNAL (FROM CUSTOMER PLC/TIMER) |

|

| OUTPUT SIGNAL "BUSY" (TO CUSTOMER PLC) |

|

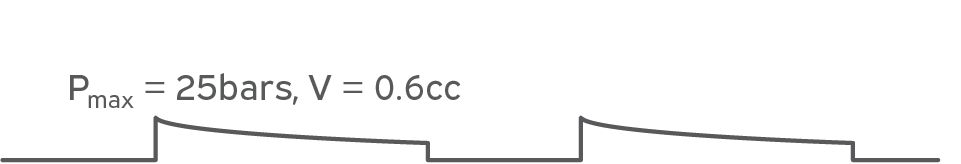

| PUMP OUTLET (TO LUBRICATION) |

|

| OUTPUT SIGNAL "DEFAULT" (TO CUSTOMER PLC) |

|

CONTINUOUS MODE

MEMOLUB VISIO PRO

| DESCRIPTION | SIGNAL |

|---|---|

| INPUT SIGNAL (FROM CUSTOMER PLC/TIMER) |

|

| OUTPUT SIGNAL "BUSY" (TO CUSTOMER PLC) |

|

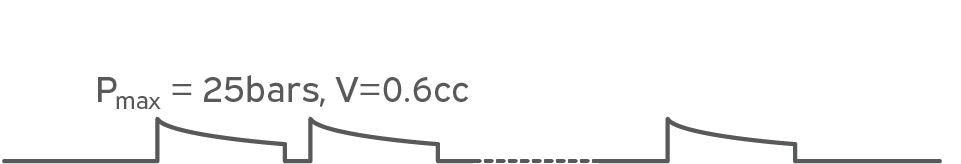

| PUMP OUTLET (TO LUBRICATION) |

|

| OUTPUT SIGNAL "DEFAULT" (TO CUSTOMER PLC) |

|

CABLE

MEMOLUB VISIO PRO

The Memolub Visio Pro is delivered with a 6 DIN x 0.25 cable with a female connector.

| DESCRIPTION | |

|---|---|

| 1. STATUS OUTPUT - (TO PLC IN) |

|

| 2. STATUS OUTPUT + (TO PLC VCC) | |

| 3. POWER SUPPLY + (12/24VAC/DC) | |

| 4. EXTERNAL INPUT IN + (FROM PLC OUT) | |

| 5. EXTERNAL INPUT IN - (FROM PLC GND) | |

| 6. POWER SUPPLY - (0VDC) |

Specifications

Electric Specifications

| MEMOLUB VISIO | MEMOLUB VISIO PRO | |

|---|---|---|

| Power Source | Battery | External |

| Voltage | 4.5V DC (3x1.5V DC AA) | 24V |

| PLC Connection | N/A | YES |

| Short circuit protection | Yes | |

| Stroke duration | 8 seconds | |

| Minimum stroke interval | 15 minutes | |

INSTALLATION GUIDELINES

DIRECT INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO PRO (2nd GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO PRO must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

MEMOLUB VISIO and MEMOLUB VISIO PRO are equipped with advanced machine learning capabilities, allowing it to account for environmental conditions when calculating its status. A learning period of 20 cycles is required, during which the lubricator must remain in the same environment without any changes to its position, fastening, support, or grease type. If any of these parameters are altered, the learning process can be reset by pressing and holding the pushbutton for more than 5 seconds.

-

1

Prime lube point and remove nipple.

-

2

Install VISIO Base using a strong threadlocker (BSP 1/4).

-

3

With setting key, choose wheel position according to "Settings" table above.

-

4

Align the pin of VISIO Module with the notch of VISIO Base.

-

5

Screw tightly keeping the assemly aligned.

-

6

Initialise Visio by pushing the button for 5 seconds.

-

7

Initialisation is confirmed by flashing each color once.

DIRECT INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO EP (1st GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO EP must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

-

1

Prime lube point and remove nipple.

-

2

Install VISIO Base using a strong threadlocker (BSP 1/4).

-

3

With setting key, choose wheel position according to "Settings" table above.

-

4

Align the pin of VISIO Module with the notch of VISIO Base.

-

5

Screw tightly keeping the assemly aligned.

-

6

VISIO initializes, flashes each color on, and makes one expulsion. Green lights confirm normal operation.

REMOTE INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO PRO (2nd GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO PRO must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

MEMOLUB VISIO and MEMOLUB VISIO PRO are equipped with advanced machine learning capabilities, allowing it to account for environmental conditions when calculating its status. A learning period of 20 cycles is required, during which the lubricator must remain in the same environment without any changes to its position, fastening, support, or grease type. If any of these parameters are altered, the learning process can be reset by pressing and holding the pushbutton for more than 5 seconds.

-

1

Prime lube point and remove nipple.

-

2

Secure the mounting bracket.

-

3

Install VISIO Base and F1/4 fitting on bracket using a strong threadlocker.

-

4

Install BSP 1/8 fitting on lube point.

-

5

Cut hose to required size.

-

6

Insert hose into bracket's quick fitting.

-

7

Insert hose into lube point's quick fitting.

-

8

With setting key, choose wheel position according to "Settings" table above.

-

9

Align the pin of VISIO Module with the notch of VISIO Base.

-

10

Screw tightly keeping the assembly aligned.

-

11

VISIO initialises, flashes each color on to confirm successful installation.

REMOTE INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO EP (1st GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO PRO must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

-

1

Prime lube point and remove nipple.

-

2

Secure the mounting bracket.

-

3

Install VISIO Base and F1/4 fitting on bracket using a strong threadlocker.

-

4

Install BSP 1/8 fitting on lube point.

-

5

Cut hose to required size.

-

6

Insert hose into bracket's quick fitting.

-

7

Insert hose into lube point's quick fitting.

-

8

With setting key, choose wheel position according to "Settings" table above.

-

9

Align the pin of VISIO Module with the notch of VISIO Base.

-

10

Screw tightly keeping the assembly aligned.

-

11

VISIO initializes, flashes each color on, and makes one expulsion. Green lights confirm normal operation.

MULTIPOINT INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO PRO (2nd GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO EP must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

MEMOLUB VISIO and MEMOLUB VISIO PRO are equipped with advanced machine learning capabilities, allowing it to account for environmental conditions when calculating its status. A learning period of 20 cycles is required, during which the lubricator must remain in the same environment without any changes to its position, fastening, support, or grease type. If any of these parameters are altered, the learning process can be reset by pressing and holding the pushbutton for more than 5 seconds.

-

1

Prime lube point and remove nipple.

-

2

Secure the mounting bracket.

-

3

Install VISIO Base and F1/4 fitting on bracket using a strong threadlocker.

-

4

Install BSP 1/8 fitting on lube point.

-

5

Cut the hoses to required size.

-

6

Insert hoses into bracket's quick fittings.

-

7

Insert hoses into lube points' quick fittings.

-

8

With setting key, choose wheel position according to "Settings" table above.

-

9

Align the pin of VISIO Module with the notch of VISIO Base.

-

10

Screw tightly keeping the assembly aligned.

-

11

VISIO initializes, flashes each color on, and makes one expulsion. Green lights confirm normal operation.

MULTIPOINT INSTALLATION MEMOLUB VISIO + MEMOLUB VISIO EP (1st GENERATION)

MEMOLUB VISIO and MEMOLUB VISIO EP must always be installed in the upright position. Failure to install the device upright may lead to potential damage to the automatic lubricator and to your equipment. Incorrect orientation will void the warranty and may pose safety risks.

-

1

Prime lube point and remove nipple.

-

2

Secure the mounting bracket.

-

3

Install VISIO Base and F1/4 fitting on bracket using a strong threadlocker.

-

4

Install BSP 1/8 fitting on lube point.

-

5

Cut the hoses to required size.

-

6

Insert hoses into bracket's quick fittings.

-

7

Insert hoses into lube points' quick fittings.

-

8

With setting key, choose wheel position according to "Settings" table above.

-

9

Align the pin of VISIO Module with the notch of VISIO Base.

-

10

Screw tightly keeping the assembly aligned.

-

11

VISIO initializes, flashes each color on, and makes one expulsion. Green lights confirm normal operation.

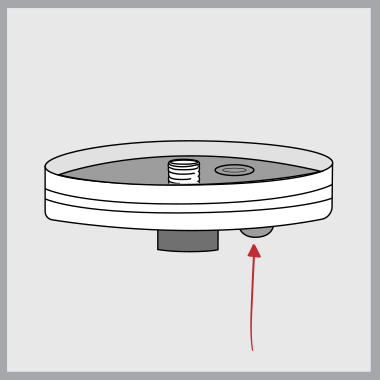

CHECK FUNCTION

2ND GENERATION

-

1

Locate the push button on the bottom of the memo.

-

2

Push the button.

-

3

Memolub Visio / Visio Pro initialises, flashing each color on successively.

-

4

Memolub Visio / Visio Pro makes 1 expulsion.

-

5

After scanning all parameters, VISIO flashes green lights in case of normal operation. For any other colors, please refer to the FAQ section.

1ST GENERATION

-

1

Locate the green triangular label indicating touchpad

-

2

Keep your fingers under VISIO Base, below the triangular sign. Blinking of the 4 green lights confirm activation of the touchpad.

-

3

Once the total touch duration has reached 5 sec, the 4 green lights are turned on simultaneously for 1s.

-

4

VISIO initializes, flashing each color on successively.

-

5

VISIO makes 1 expulsion.

-

6

After scanning all parameters, VISIO flashes green lights in case of normal operation. For any other colors, please refer to the FAQ section.

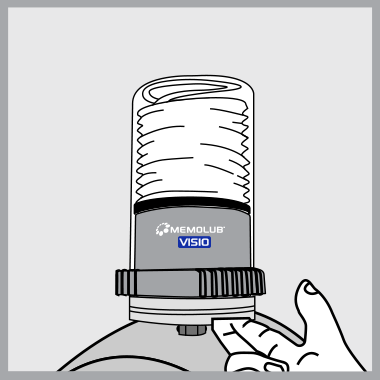

REFILL GUIDELINES

CARTRIDGES

-

1

Remove VISIO Module from VISIO Base.

-

2

Open VISIO Module (fingers on ribs).

-

3

Prime VISIO Pump.

-

4

Insert new battery pack and seal. NOTE: the battery seal can be removed for 480cc cartridges

-

5

Squeeze air out of the cartridge.

-

6

Replace the cartridge on VISIO Pump.

-

7

Close and lock VISIO Module (fingers on ribs).

-

8

Align the pin of VISIO Module with the notch of VISIO Base.

-

9

Screw tightly keeping the assembly aligned.

-

10

VISIO initializes, flashes each color on, and makes one expulsion. Green light confirms proper functioning.

FAQ

-

Nothing happens after screwing the module on the base.

- The pin of the module is possibly not proper aligned with the notch of the base. Unscrew the module from the base, align correctly and screw it again.

- Memolub VISIO Series is not tightly screwed to the memo. Turn it clockwise until stop.

- There is possibly no battery inside the module. Insert 3x 1,5 VDC AA batteries to resolve the issue.

- There is possibly something obstructing the communication between the base and the module contacts. Unscrew the module from the base, remove any dust or obstacles from the base and the module contacts and screw back together tightly.

-

The touchpad does not work after initialisation was completed successfully.

Your Memolub VISIO Series possibly initialised in an unstable environment. Unscrew the base from the module and screw again to reset the system. Wait until one expulsion is performed and you observe green lights, indicating the initialization is complete.

-

The red lights are blinking periodically.

- There is possibly a too high back pressure present in the system. Inspect your downstream piping to remove any clogging or jam. Activate the touchpad and check for at least 2 expulsions if the systems operate fine.

- There is possibly something obstructing the communication between the base and the module contacts. Unscrew the module from the base, remove any dust or obstacles from the base and the module contacts and screw back together tightly.

- The motor is broken. Replacement of the module is necessary.

- There is possibly a too high back pressure present in the system. Inspect your downstream piping to remove any clogging or jam. Activate the touchpad and check for at least 2 expulsions if the systems operate fine.

-

The yellow lights are blinking periodically.

- There is possibly something obstructing the communication between the base and the module contacts. Unscrew the module from the base, remove any dust or obstacles from the base and the module contacts and screw back together tightly.

- The batteries are empty. Replacement of the battery pack is necessary.

- There is possibly something obstructing the communication between the base and the module contacts. Unscrew the module from the base, remove any dust or obstacles from the base and the module contacts and screw back together tightly.

-

The blue lights are blinking periodically.

- The cartridge is possibly out of grease. Replacement of the cartridge is necessary.

- The system is not primed. Prime the system using a manual grease pump.

- The system is operating out of its minimum and maximum temperature range. Please make sure the system is operating within the recommended temperature range.

- The cartridge is possibly out of grease. Replacement of the cartridge is necessary.

REGULATORY INFORMATION

| SYMBOL | DESCRIPTION |

|---|---|

|

|

This product is compliant with Directives 2006/42/EC (Machinery). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with UK regulations 2008 No. 1597 (Supply of Machinery). The relevant Declaration of Conformity is available here. |

|

|

This product is compliant with customs union technical regulation TR CU 010/2011 (safety of machines and equipment). The relevant Declaration of Conformity is available here. |

|

|

The WEEE symbol is attached to the product in compliance with the EU directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE). It is intended to deter the improper disposal of this product and to promote reuse and recycling. |

|

|

The packaging material can be recycled. Please arrange for the environmental appropriate disposal of the packaging. |